Epoxy Tile Grout vs. Cement Sealant: Making the Right Choice for Professional Applications

In the world of construction and industrial maintenance, the selection of materials can make or break a project. Among the many decisions professionals face is the choice between epoxy tile grout and cement sealant—two fundamentally different solutions for filling and protecting gaps in surfaces.

While both serve the basic purpose of sealing gaps, their properties, performance characteristics, and ideal applications differ significantly. Understanding these differences is crucial for architects, contractors, and facility managers who need to make informed decisions that will affect the longevity, maintenance requirements, and overall success of their projects.

Understanding the Basics: Fundamental Composition Differences

Epoxy Tile Grout: Advanced Polymer Technology

Epoxy Tile Grout: Advanced Polymer Technology

Epoxy tile grout is a two-component system typically consisting of epoxy resin and a hardener. When these components are mixed, they undergo an irreversible chemical reaction that creates a extremely durable, non-porous material. Modern epoxy grouts often include fillers like quartz sand for added strength and wear resistance. The result is a product that delivers exceptional performance in challenging environments.

The technology behind epoxy grout has evolved significantly over the years. Today's formulations offer enhanced workability, color consistency, and chemical resistance compared to earlier versions that were difficult to work with and prone to discoloration.

Cement Sealant: Traditional Mineral-Based Solution

Cement sealant, also known as cement-based grout or concrete sealant, is primarily composed of cement, fine aggregates (such as quartz sand), and various additives that improve workability, water retention, or setting characteristics. Some formulations may include polymers to enhance flexibility and adhesion.

Unlike epoxy grout which creates a completely new material through chemical reaction, cement sealant hardens through hydration—the same process that sets ordinary concrete. This fundamental difference in curing mechanism explains many of the performance differences between the two products.

Performance Characteristics: A Detailed Comparison

To make an informed choice between epoxy tile grout and cement sealant, professionals need to understand how these materials perform across various critical parameters. The following table provides a comprehensive comparison:

| Performance Characteristic | Epoxy Tile Grout | Cement Sealant |

|---|---|---|

| Compressive Strength | Extremely high (>60 MPa) | Moderate (15-30 MPa) |

| Flexural Strength | High resistance to cracking | Prone to cracking under movement |

| Chemical Resistance | Excellent against acids, alkalis, solvents | Poor to moderate, especially against acids |

| Water Resistance | Virtually impermeable (waterproof) | Absorbs water, can harbor mildew |

| Abrasion Resistance | Exceptional wear resistance | Moderate, deteriorates over time |

| Color Stability | Excellent, UV-resistant options available | Prone to fading and discoloration |

| Shrinkage During Curing | Minimal to none | Significant, can pull away from edges |

| Service Life | 20+ years in most applications | 5-10 years before needing replacement |

| Maintenance Requirements | Low, easy to clean | High, requires regular sealing |

| Application Complexity | Moderate to high, requires skill | Relatively simple, forgiving |

Chemical and Stain Resistance: A Critical Difference

Epoxy grout creates a non-porous surface that resists virtually all common chemicals, including acids, alkalis, oils, and solvents. This makes it indispensable in environments where spills occur, such as food processing plants, laboratories, and healthcare facilities.

Cement sealant, being porous by nature, absorbs liquids readily. This leads to staining and can create breeding grounds for bacteria and mold. While sealers can improve resistance, they wear away over time and require reapplication to maintain protection.

Mechanical Strength and Durability

The superior bond strength of epoxy grout—often 2-3 times greater than cementitious products—makes it resistant to impact and heavy traffic. This exceptional durability translates to reduced maintenance costs and longer service life, even in high-traffic areas like airports, shopping malls, and industrial facilities.

Cement sealant offers adequate strength for many residential and light commercial applications but is more prone to cracking and crumbling over time, especially in environments with vibration or structural movement.

Introducing Our Premium Epoxy Grout Solution

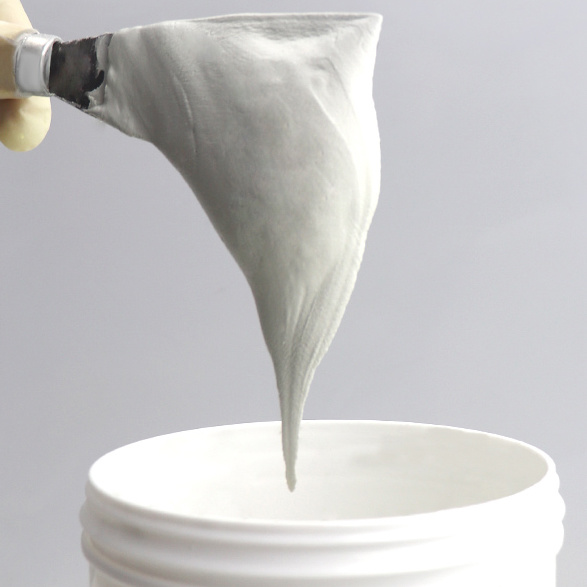

Professional application of our premium epoxy grout in a commercial kitchen setting

At Advanced Building Solutions, we've developed a next-generation epoxy tile grout that represents the culmination of years of research and field testing. Our UltraGuard Epoxy Grout System combines the best properties of traditional epoxy grouts with significant improvements in workability and aesthetics.

Key Product Features:

Enhanced Color Consistency: Advanced pigment technology ensures uniform color throughout application and over time.

Extended Working Time: Proprietary formulation gives installers 45% more working time compared to standard epoxy grouts without compromising cure time.

Low-Odor Formula: Our revolutionary formula reduces volatile organic compounds (VOCs) by 70% compared to conventional epoxy grouts.

Superior Flexibility: Micro-flex technology allows for movement up to 2.5mm without cracking, making it ideal for environments with vibration or thermal expansion.

UV Resistance: Unlike many epoxy grouts that yellow with UV exposure, our formulation includes UV stabilizers that maintain color fidelity in naturally lit areas.

Conclusion: Investing in Long-Term Performance

The choice between epoxy tile grout and cement sealant represents a fundamental decision between short-term economy and long-term performance. While cement sealants have their place in certain applications, epoxy grout delivers unparalleled performance in demanding environments where failure is not an option.

As building professionals increasingly focus on life-cycle costs, sustainability, and hygienic environments, the shift toward high-performance materials like epoxy grout will continue to accelerate. By understanding the properties, applications, and economic implications of both products, specifiers can make informed decisions that balance performance requirements with budget considerations.

The future of grouting technology continues to evolve with nanotechnology additions, even more user-friendly formulations, and enhanced sustainability profiles. Whatever developments emerge, the fundamental advantages of epoxy chemistry will likely maintain its position as the premium choice for professionals who value performance, durability, and long-term value.

Summary:

Time:

2025-09-03

More News