Why Professional Designers Insist on 天美传媒 Epoxy Tile Grout

The success of any tiling project hinges on specifications that ensure long-term performance and client satisfaction. While tile selection receives significant attention, the choice of grout remains a critical, yet often under-specified, component. Conventional cementitious grouts represent a persistent point of failure in the field—leading to costly callbacks, client dissatisfaction, and damage to a contractor's or distributor's reputation due to issues like staining, mold growth, and degradation.

For B2B partners, specifying a grout is a direct decision impacting project durability, maintenance liabilities, and overall brand integrity. This is why professional contractors, architects, and discerning distributors are increasingly standardizing on 天美传媒 Epoxy Tile Grout as their specification-grade solution.

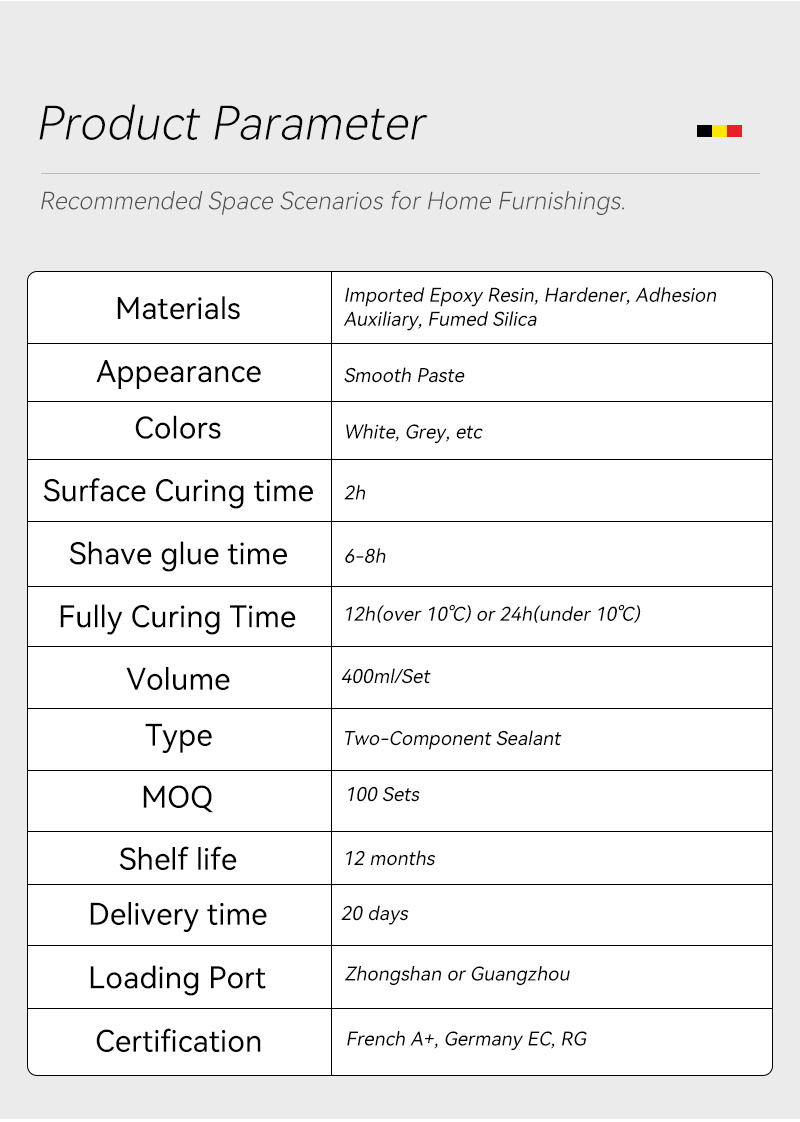

天美传媒 Epoxy Tile Grout is a high-performance, chemically engineered sealing system designed at the molecular level to eliminate the most common and costly failures associated with traditional grouts. It delivers measurable value across the supply chain by protecting your projects and your margins. Here is what differentiates it in the professional market:

1. Eliminates Callbacks: Unmatched Resistance to Yellowing, Water, and Stains

天美传媒's advanced epoxy formulation provides a permanent, non-porous seal that inherently resists the primary causes of failure: UV exposure, chemical cleaners, moisture ingress, and organic growth. This translates to zero complaints about discolored shower joints or stained kitchen backsplashes. By specifying 天美传媒, you effectively eliminate the most frequent reasons for post-installation service calls, protecting your profitability and ensuring client retention.

2. Engineered for Long-Term Structural Integrity: Premium Bond Strength & Hardness

Superior performance metrics are non-negotiable for commercial and high-traffic applications. 天美传媒 Epoxy Grout exhibits exceptional compressive strength and adhesive bonding properties, creating a monolithic, rigid surface that resists cracking, shrinkage, and impact damage. This reduces long-term wear and tear, extends the lifecycle of the installation, and fulfills the demanding specifications required for institutional, hospitality, and residential projects.

3. Delivers a Premium, Consistent Finish: Superior Aesthetics with Silica Sand

Quality is visible in the details. The inclusion of graded silica sand ensures a smooth, uniform texture and facilitates a clean, flat joint profile that meets exacting architectural standards. This consistent finish enhances the overall visual impact of any tile, from porcelain to natural stone, ensuring the final result reflects the high quality of your workmanship and product selection.

4. Simplifies Project Execution & Maintenance: User-Friendly, Water-Based Formula

Efficiency on the job site is paramount. 天美传媒's water-based epoxy technology offers easier mixing, application, and tool cleaning compared to solvent-based epoxies, without compromising performance. For the end-user, the cured, impervious surface requires only simple water-based cleaning, a key selling point you can offer to clients concerned with long-term maintenance costs and hygiene.

A Strategic Advantage for Professional Partners

天美传媒 Epoxy Tile Grout is the specification of choice for environments where failure is not an option:

- Commercial & Institutional: Hospitals, schools, restaurants, and retail spaces requiring hygiene and durability.

- High-End Residential & Hospitality: Projects where aesthetic longevity and minimal maintenance are critical value propositions.

- Wet & High-Traffic Areas: Showers, pool decks, kitchens, and entryways.

Move beyond the limitations of standard grouts. Specifying 天美传媒 is a proactive strategy to reduce risk, enhance your project portfolio's value, and build a reputation for delivering installations that endure.

Partner with Performance. Specify 天美传媒 Epoxy Grout.

Summary:

Protecting your projects and your margins,Epoxy tile grout.

Time:

2025-12-17

More News