Epoxy Tile Grout vs. Cement-Based Grout: Making the Strategic Choice for Professionals

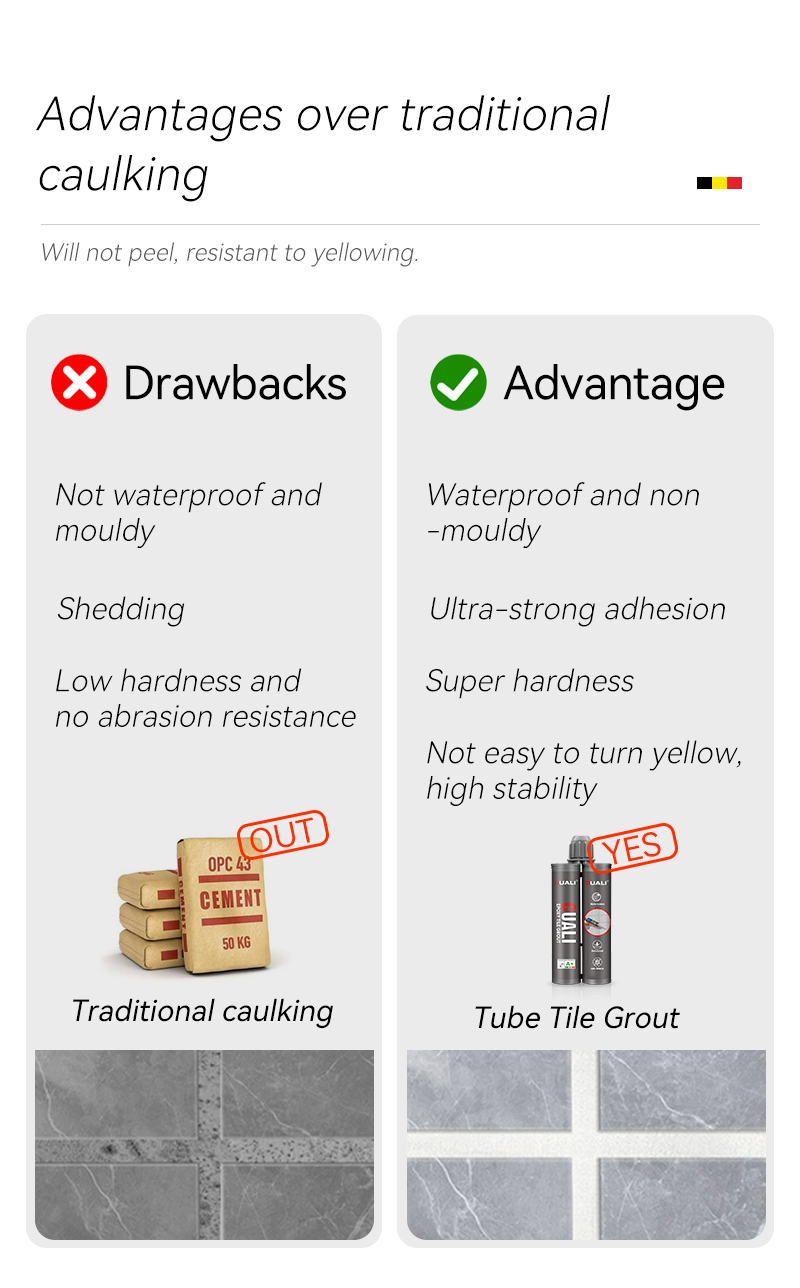

The non-porous surface of epoxy grout effectively resists chemical erosion and bacterial growth, excelling in demanding environments like laboratories. In contrast, cement-based grout hardens through the traditional Portland cement hydration process, its porous structure presenting significant weaknesses in damp or chemical-heavy settings.

As the construction industry places increasing emphasis on durability, hygiene standards, and life-cycle costs, the underlying logic of material selection is undergoing a profound shift. The choice made today directly impacts maintenance costs and operational safety for decades to come.

02 Critical Performance Face-Off

The practical performance differences are stark and dictate their respective ideal applications. The table below details their comparison across key metrics:

| Performance Metric | Epoxy Tile Grout | Cement-Based Grout |

|---|---|---|

| Compressive Strength | Very High (> 60 MPa) | Moderate (15-30 MPa) |

| Chemical Resistance | Excellent; resists acids, alkalis, oils, solvents. | Poor to moderate; particularly vulnerable to acids. |

| Water Resistance | Virtually impermeable (waterproof). | Absorbs water; can foster mold/mildew. |

| Abrasion Resistance | Exceptional; handles heavy foot/vehicle traffic. | Moderate; wears down over time. |

| Color Stability | Excellent; UV-resistant formulas available. | Prone to fading/discoloration, especially in sunlight. |

| Shrinkage During Cure | Minimal to none. | Significant; can pull away from edges. |

| Expected Service Life | 20+ years. | Typically 5-10 years before repair/replacement. |

| Maintenance Demands | Low; smooth surface is easy to clean. | High; requires periodic sealing. |

Epoxy’s impermeable surface makes it ideal for demanding environments where spills of chemicals, cleaning agents, oils, and colored liquids are routine, such as labs, food processing plants, and commercial kitchens.

The porosity of cement-based grout is its critical flaw. Liquids are absorbed into the material, leading to stubborn stains and creating a breeding ground for bacteria and mold, even with sealers.

03 Mapping the Right Material to the Right Application

Based on these performance profiles, the two materials have clear boundaries in practice. Cement-based grout retains value in budget-conscious residential or light commercial projects with mild conditions, like a low-traffic home bathroom, when paired with regular sealing maintenance.

Epoxy grout is the mandatory choice for high-performance, high-demand scenarios:

- Food & Beverage Plants & Commercial Kitchens: Must withstand frequent chemical cleaning, steam, grease, and meet strict hygiene codes.

- Laboratories & Healthcare Facilities: Requires resistance to chemical reagents and disinfectants, offering a sterile, easily cleaned surface.

- Heavy Industry & Warehousing: Must endure impact from forklifts, resist oils, and satisfy long-life, low-maintenance needs.

- High-Traffic Public Transit Areas: Airports, malls, and subway stations need superior abrasion and stain resistance.

Here, while epoxy's initial cost and required installation expertise are higher, its extended lifespan and minimal upkeep often result in a lower total cost of ownership.

04 The Professional's Decision Framework

For any project, a systematic evaluation is key:

- Primary Consideration: The Environment. Assess exposure to chemicals, temperature fluctuations, moisture levels, hygiene standards, and expected traffic load. In corrosive, frequently washed, or perpetually damp settings, epoxy's advantages are decisive.

- Calculate Total Life-Cycle Cost. Look beyond initial install. Factor in long-term maintenance, repair frequency, and potential business interruption from repairs. Epoxy's "install-and-forget" nature offers significant economic benefit in commercial operations.

- Assess Installation Practicalities. Epoxy demands precise substrate preparation, mixing, controlled conditions, and skilled installers. Ensure the project timeline and crew expertise align with these requirements.

A final, pragmatic recommendation: conduct a physical mock-up in an inconspicuous yet representative project area. Observing how both materials perform under simulated real-world conditions is the most reliable verification method.

Summary:

Epoxy grout is the mandatory choice for high-performance, high-demand scenarios

Time:

2025-12-26

More News